Tall oil

Choose the green one

Although the paint in the buckets is exactly the same, there is an important difference. The one on the right is actually green, as it contains Liquid Forest™ Tall Oil from Södra.

Tall oil is perhaps the most versatile of all forest products. Among other things, it is used in the production of biofuels and it can be fractionated into many substances with widely different properties.

Our tall oil can be found in a huge variety of products and processes, where it often replaces fossil-based substances. Everywhere around you there is tall oil – in soap, glue, tape, facade and wall paints, and countless other products. And together with our customers we keep finding more uses. With a renewable raw material, the opportunities will never stop growing.

How we produce tall oil

Depending on the raw material used at our pulp mills, Södra has the capacity to produce about 46,000 tonnes of tall oil (crude tall oil) per year.

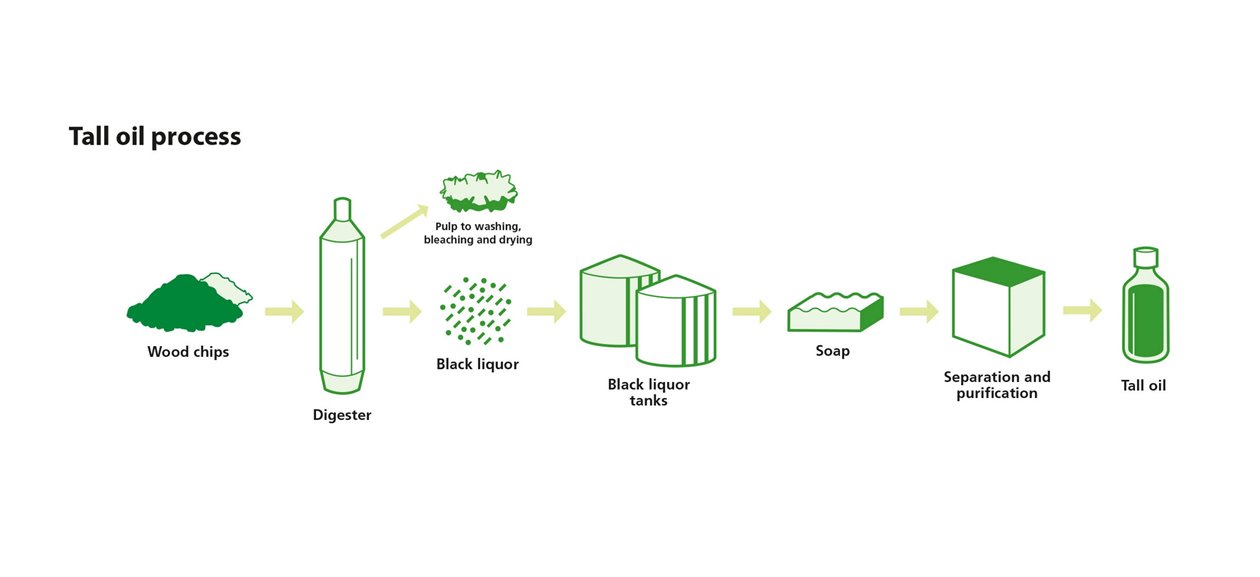

After the cooking process where wood chips become pulp, the spent cooking liquor – black liquor – is taken through a chemical recycling process. In the black liquor there are extractives that have been separated from the wood and turned into soap. This soap, in turn, can be separated from the black liquor by decantation in black liquor tanks.

The soap is then treated with acid to return to various organic acids – and the product is called crude tall oil. The name tall oil is used regardless of wood type in the raw material.

Tall oil, lower climate impact

Every year, our Liquid Forest™ Tall Oil helps reduce the climate impact of the biofuel industry by about 90,000 tonnes of carbon dioxide. Sounds like a lot, you might say – and it is. The amount of saved carbon dioxide corresponds to a return trip to the sun by car, twice over.

Another important environmental aspect is that the raw material for our tall oil already exists inside our regular production. It’s simply a product of maximum resource utilisation – using the entire tree – at our pulp mills.

The raw material for our tall oil comes from the sustainable forests of our members. Since these members comprise tens of thousands of small-scale forest owners, each with their own goals and visions, it contributes to the variety and diversity in the Swedish forest. About 70 percent of our members are FSC® and/or PEFC™ certified.

Technical data sheets

Related links